What is Oxide Strip?

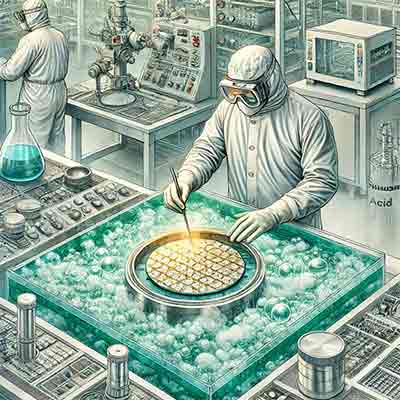

Oxide strip refers to the process of removing silicon oxide (SiO₂) from the surface of a silicon wafer or other materials. This process is commonly used in semiconductor and microfabrication industries to prepare the surface for further processing or to remove unwanted oxide layers formed during previous steps.

Key Methods for Oxide Stripping

1. Wet Chemical Etching

- Buffered Oxide Etch (BOE): A solution of hydrofluoric acid (HF) mixed with buffering agents like ammonium fluoride (NH₄F). BOE is widely used because it offers better control over etching rates.

- Dilute Hydrofluoric Acid (DHF): Pure HF diluted with water. Effective for fast and aggressive oxide removal.

2. Dry Etching (Plasma Etching)

Uses reactive ion etching (RIE) or other plasma-based techniques to remove oxide layers with high precision. This method is ideal for selective or patterned oxide removal.

3. Vapor-Phase Etching

Uses vaporized HF and sometimes water vapor to etch SiO₂. Preferred for delicate structures, as it avoids capillary forces seen in liquid-based etching.

Applications of Oxide Stripping

- Surface Preparation: Ensures a clean silicon surface for deposition, lithography, or bonding processes.

- Patterning: Used in conjunction with masking to create specific oxide patterns for microelectronic or MEMS devices.

- Device Fabrication: Removes oxide layers after they have served their purpose as a protective layer, diffusion barrier, or masking material.

- Native Oxide Removal: Removes the naturally formed thin SiO₂ layer on silicon surfaces.

Considerations in Oxide Strip Processes

- Selectivity: Ensures the underlying material (e.g., silicon or metal) is not etched.

- Etch Rate: Depends on the type of oxide, its thickness, and the stripping method used.

- Cleanliness: Residues from chemical stripping must be thoroughly cleaned to avoid contamination.

- Safety: Hydrofluoric acid is extremely hazardous, requiring careful handling and proper protective equipment.